Considerations To Know About gearbox cvt

Considerations To Know About gearbox cvt

Blog Article

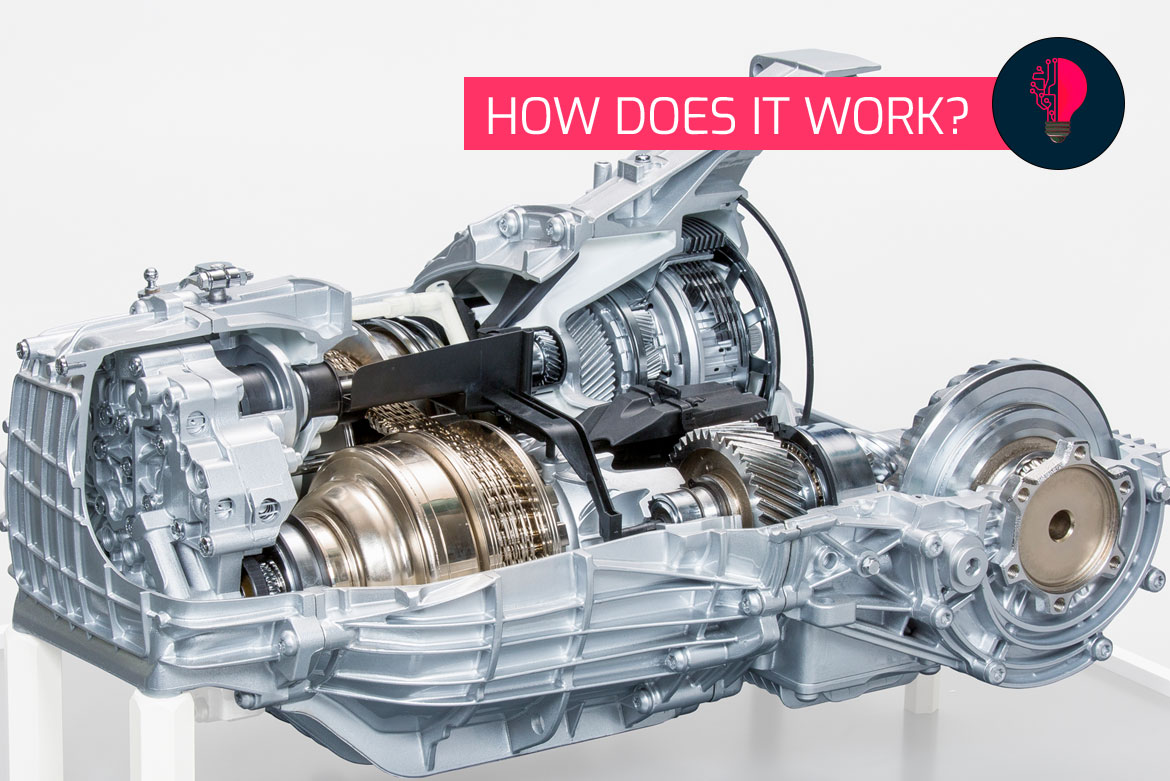

A constantly variable transmission (CVT) is often a style of automated transmission that's been getting attractiveness recently. Not like classic automated transmissions that make use of a set range of gears, CVTs make use of a belt and pulley process that gives an infinite variety of gear ratios.

Signs: Sluggish acceleration, lousy reaction to throttle input, or perhaps a recognizable fall in engine performance when accelerating.

[1] This contrasts with other transmissions that provide a constrained range of gear ratios in fixed methods. The flexibility of a CVT with suited Command might allow the motor to operate at a constant angular velocity although the car or truck moves at various speeds.

nine MPG. In the short time frame I've owned it I don’t have any grievances on or from the highway. This is a 4WD, but I haven't been off street or operated on snow/ice covered roads. I do stay up for striving.

CVT gearboxes are rather very simple of their structure and design and have been in production for many years, so they’re fairly dependable as a result. Providing you persist with a daily company routine, a CVT needs to be no a lot more problematic than a conventional automated gearbox.

And pace ratios are achieved when v-belt rotates at the upper cross segment of the input pulley and lessen cross-section in the output pulley.

This flexibility helps make CVTs significantly useful in present day vehicles the place performance dapatkan produk and effectiveness are paramount.

No gears means basic upkeep. Another matter we like with regards to the CVT is comparatively simple engineering. You might get diverse thoughts from various engineers on this, but by and large, The easy engineering of the CVT with just a few transferring areas interprets to Significantly less complicated maintenance.

CVTs get noticed from conventional transmissions because of their special capacity to improve seamlessly via an infinite quantity of helpful equipment ratios in between greatest and minimum values.

The result is often a smoother, much more efficient and quicker travel than an typical computerized. There is a downside while, Which’s the energy losses resulting from friction are larger having a CVT – about 5 to 15% according to the style, whereas with usual gears it’s more like two-5%. As at any time, growth is closing the hole, and The actual fact the CVT will allow the engine to stay in its ideal rev changes much more than compensates for the extra effectiveness decline.

I’ve also read that somebody is experimenting by using a tourque converter also. Could you elaborate ? Many thanks.

When the facility output is too minimal, the generator is disconnected, as well as Strength is stored within the flywheel. It is just once the velocity in the flywheel is sufficient the kinetic energy is transformed into energy, intermittently, for the speed essential from the generator.

System: It employs a hydraulic pump and motor to transform mechanical Vitality to hydraulic stress and back, allowing for ongoing variation in equipment ratios.

Within a hydrostatic CVT, the productive "equipment ratio" between the motor as well as driving wheel(s) is the results of a difference between the pump's displacement—expressed as cubic inches or cubic centimeters for each revolution—and also the motor's displacement.